Opportunities, Challenges, and the Road Ahead

By MYBRANDBOOK

India’s semiconductor industry is at a critical juncture, with the government and private sector making significant strides to position the country as a global hub for semiconductor manufacturing and design. With burgeoning demand for electronic devices, coupled with strategic policy support, the Indian semiconductor ecosystem is poised for substantial growth. However, the path forward is laden with challenges that need to be addressed to realize this potential fully.

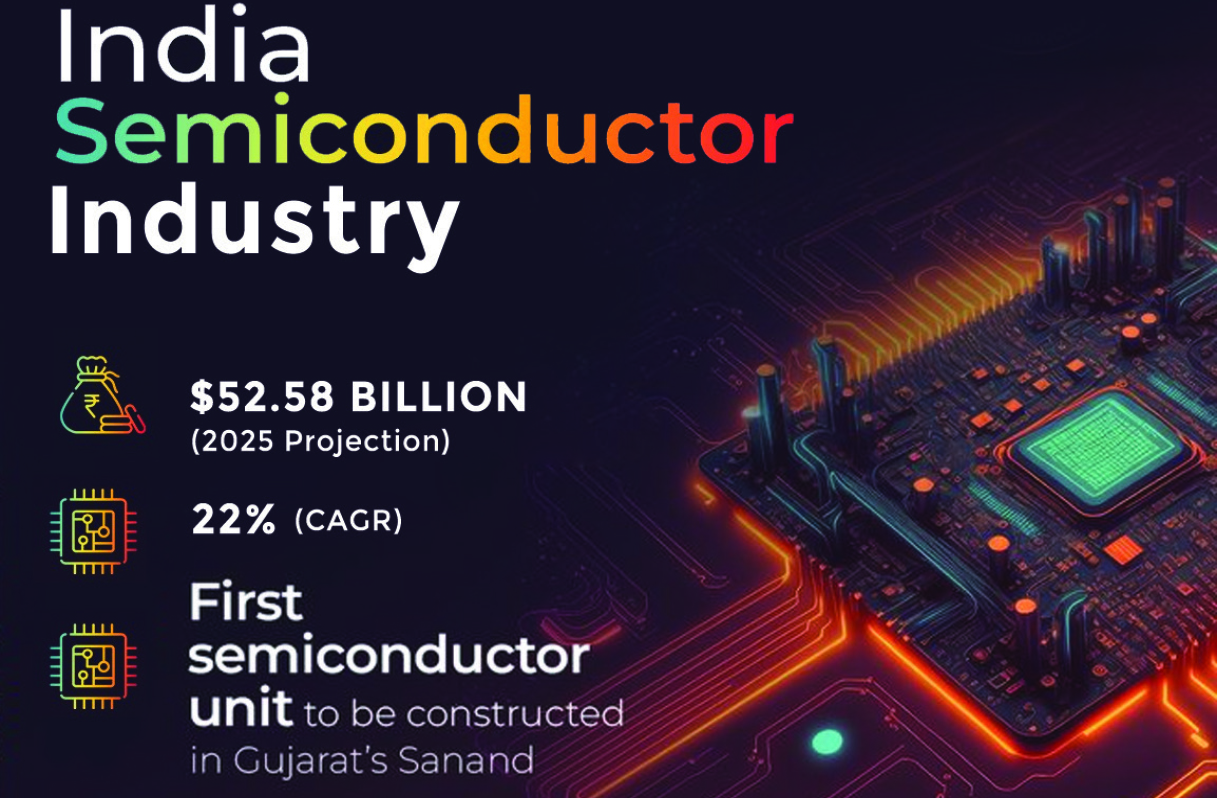

Market Size

According to the India Electronics and Semiconductor Association (IESA), the Indian semiconductor market is projected to reach $52.58 billion by 2025, growing at a compound annual growth rate (CAGR) of 22%. The demand for semiconductors in India is driven by the automotive industry, consumer electronics, and the rapid proliferation of the Internet of Things (IoT) devices.

In 2020, India imported approximately $14 billion worth of semiconductors, underscoring the urgent need to develop domestic manufacturing capabilities to reduce dependence on imports and enhance supply chain resilience.

India is emerging as a significant consumer of semiconductors, with its market valued at $22 billion in 2019. According to Counterpoint Technology Market Research, this market is projected to nearly triple, reaching $64 billion by 2026. The country’s Minister of State for IT and Electronics, Rajeev Chandrasekhar, anticipates even further growth, predicting the market will soar to $110 billion by 2030. At that level, India would account for 10 percent of global semiconductor consumption, as highlighted in the IT&IF report.

Government Initiatives and Policy Support

The Indian government has recognized the strategic importance of the semiconductor industry in achieving self-reliance in technology and driving economic growth. In December 2021, the government launched the $10 billion incentive scheme aimed at boosting semiconductor and display manufacturing. The scheme offers fiscal support for setting up semiconductor fabs, display fabs, and other facilities involved in semiconductor manufacturing. This initiative is part of the broader “Make in India” and “Digital India” campaigns, which aim to foster innovation and enhance India’s manufacturing capabilities.

The Production-Linked Incentive (PLI) Scheme, specifically targeting large-scale electronics manufacturing, is another significant policy measure. The PLI scheme provides financial incentives to boost domestic manufacturing and attract investments in the electronics sector. The extension of this scheme to the semiconductor industry is expected to create an ecosystem conducive to semiconductor manufacturing.

Major Investments

The Indian government, in February 2024, has approved a significant investment in semiconductor and electronics production, which will feature the country’s first advanced semiconductor fab. Three new facilities—one semiconductor fab and two packaging and test facilities—are set to begin construction within 100 days. This initiative includes an allocation of 1.26 trillion Indian rupees (US $15.2 billion).

India joins a global effort to enhance domestic chip manufacturing, aiming to reduce dependence on foreign supply chains in this strategically vital industry.

The First Semiconductor Fab

The first semiconductor fab will be a joint venture valued at $11 billion between Taiwan’s PSMC and Tata Electronics, part of the $370 billion Tata Group. This facility will produce chips at 28-, 40-, 55-, and 110-nanometer nodes, with a monthly capacity of 50,000 wafers. Although not cutting-edge, these nodes are widely used in the industry, with 28 nm being the most advanced node using planar CMOS transistors rather than FinFET devices.

Tata Electronics highlights that the fab will manufacture chips for applications including power management, display drivers, microcontrollers, and high-performance computing logic. These products were critically affected during the pandemic-era chip shortage. Located in Dholera, Gujarat, the fab is expected to generate over 20,000 skilled jobs directly and indirectly.

Packaging and Test Facilities

In Jagiroad, Assam, Tata Electronics will establish a $3.25 billion plant. This facility will offer various packaging technologies, including wire bond, flip-chip, and system-in-package. There are plans to expand into advanced packaging technologies such as 3D integration, which has become vital as traditional transistor scaling slows down and becomes costlier. The plant aims to commence production in 2025 and is projected to create 27,000 direct and indirect jobs.

Another significant investment comes from a joint venture between Renesas, Stars Microelectronics, and India’s CG Power and Industrial Solutions. This $900 million packaging plant in Sanand, Gujarat, will offer wire-bond and flip-chip technologies. CG Power will hold a 92 percent stake in the venture.

Additionally, U.S.-based Micron Technology is building a chip-packaging and test facility in Sanand under an earlier agreement. Micron plans to invest $825 million over two phases, with the Gujarat and Indian federal governments covering an additional $1.925 billion. The first phase is expected to be operational by the end of 2024.

These investments highlight India’s strategic push to become a significant player in the global semiconductor landscape, leveraging local talent and fostering technological innovation.

Surge of Semiconductor GCCs in India

India is witnessing a remarkable rise in Semiconductor Global Capability Centers (GCCs). In the fourth quarter of 2023, semiconductor GCCs accounted for approximately 30% of the new GCC establishments in the country. This trend underscores a growing inclination towards harnessing local expertise for front-end design, performance testing, and post-silicon validation.

Bengaluru, often referred to as India’s Silicon Valley, is leading the charge in the semiconductor GCC landscape. The city houses about 42% of all semiconductor GCC units in India and boasts 61% of the nation’s semiconductor talent pool. Hyderabad is also emerging as a significant player, hosting 23% of the semiconductor GCC units and 21% of the talent in the country.

India’s semiconductor landscape is being reshaped by several key players, both domestic and international, each bringing substantial investments and technological expertise. Here’s a detailed look at some of the prominent companies and their strategic plans to establish and expand semiconductor operations in India.

Key Semiconductor GCC Units in India

Signature IP: Signature IP, a US-based company founded in 2021, focuses on network-on-chip (NoC) technology. In October 2023, the company established a GCC in India and launched an R&D center in Bhubaneswar to innovate NoC solutions and collaborate with local institutions.

EdgeCortix: a fabless semiconductor firm from Japan has set up a GCC in Hyderabad. Specializing in AI-specific processor architecture, the company offers a comprehensive AI inference software development environment and reconfigurable edge AI chips. Their Dynamic Neural Accelerator IP core stands out with a significant performance boost over GPUs.

M31 Technology: Taiwan-based M31 Technology Corporation opened its first overseas R&D design center in Bengaluru in October 2023. The center focuses on IP development, IC design, and EDA, reinforcing M31’s global reach.

Micron: Micron Technology is investing $2.75 billion in a new semiconductor facility in Sanand, Gujarat, focusing on DRAM assembly and testing. The project, supported by both central and state governments, is set to create up to 20,000 jobs and will significantly enhance Micron’s production capacity.

The company plans to start construction this year, with Phase 1 (500,000 sq ft cleanroom) which would be operational by late 2024. Phase 2, similar in scale to Phase 1, is slated to start in the latter half of the decade.

AMD: AMD has inaugurated its largest global design center in Bengaluru. This new campus, with a 500,000 square feet area and part of AMD’s $400 million investment over five years, plans to employ around 3,000 engineers to work on high-performance CPUs, GPUs, SoCs, and FPGAs.

Texas Instruments: Texas Instruments (TI) has been a pioneer in India since 1985. Its Bengaluru center has evolved into a crucial R&D hub, contributing significantly to TI’s global product development.

Nvidia: Nvidia has four engineering centers in India and collaborates with major Indian firms to build advanced AI data centers. This collaboration leverages Nvidia’s cutting-edge technology to enhance AI capabilities across the country.

Qualcomm: Qualcomm has strengthened its presence in Chennai with a new design center, part of a Rs 177.27 crore investment. With additional centers in Bengaluru, Hyderabad, and Delhi, Qualcomm employs 4,000 engineers in India, focusing on global 5G R&D efforts.

Tata Group: Tata Group, one of India’s largest and most influential conglomerates, has made a significant move into the semiconductor sector. In 2021, Tata announced plans to set up a $300 million semiconductor assembly and test unit. This facility will focus on semiconductor packaging and testing, a crucial part of the semiconductor manufacturing process. Tata’s foray into this domain aligns with its broader strategy to diversify its technology portfolio and tap into the growing demand for semiconductors in India and globally.

The Tata Group’s entry into the semiconductor industry is expected to leverage its vast industrial experience and robust infrastructure. This initiative is not just a business expansion but a strategic move to position India as a significant player in the global semiconductor supply chain. Tata’s venture is anticipated to create numerous high-tech jobs and foster innovation in semiconductor technology within India.

Vedanta-Foxconn: Vedanta, a major player in the mining and metals industry, has partnered with Foxconn, the world’s largest contract electronics manufacturer, to invest $15 billion in setting up semiconductor and display manufacturing units in India. This collaboration is a landmark development, given Foxconn’s extensive experience in electronics manufacturing and Vedanta’s strong industrial presence in India.

The Vedanta-Foxconn joint venture aims to establish semiconductor fabrication plants and display fabs, which are essential for producing integrated circuits and display panels used in a variety of electronic devices. The project is expected to significantly boost India’s capabilities in semiconductor manufacturing and reduce dependence on imports. This partnership underscores the confidence global companies have in India’s potential to become a semiconductor manufacturing hub.

ISMC Digital: ISMC Digital, a consortium of Abu Dhabi-based Next Orbit Ventures and Israel’s Tower Semiconductor, has committed $3 billion to establish a semiconductor manufacturing facility in Karnataka. This plant will have a capacity of 40,000 wafers per month, focusing on analog semiconductors used in automotive, consumer, and industrial applications.

Tower Semiconductor, a key player in analog integrated circuits, brings significant technological expertise to this venture. The ISMC project is expected to create a robust ecosystem for analog semiconductor manufacturing in India, complementing the country’s efforts to diversify its semiconductor capabilities.

Intel: While Intel has not announced specific manufacturing plans in India, the company continues to expand its R&D and design capabilities in the country. Intel’s significant investment in research and development centers in Bangalore and Hyderabad underscores its long-term commitment to India’s semiconductor landscape. Intel operates several GCCs in India, primarily for chip design and development. Although it currently does not manufacture chips in India, Intel collaborates with institutions like IIT Bombay to foster semiconductor research.

TSMC (Taiwan Semiconductor Manufacturing Company): As the world’s largest semiconductor foundry, TSMC is a crucial player in the global semiconductor industry. TSMC has expressed interest in India as a potential location for future investments, given the country’s strategic importance and supportive government policies. Although no specific plans have been finalized, TSMC’s interest signals a positive outlook for India’s semiconductor ambitions.

Samsung: Samsung, a global leader in memory and logic chip manufacturing, has been expanding its semiconductor business worldwide. The company has shown interest in India’s semiconductor sector, particularly in setting up advanced semiconductor fabrication plants. Samsung’s existing presence in India’s consumer electronics and mobile manufacturing sectors provides a solid foundation for expanding into semiconductor manufacturing.

Homegrown Initiatives

In addition to global giants, several Indian companies are making strides in the semiconductor domain:

Bharat Electronics Limited (BEL): BEL, a leading state-owned enterprise in defense electronics, is exploring semiconductor manufacturing opportunities. The company plans to diversify its product portfolio to include semiconductors used in defense and aerospace applications.

SCL (Semiconductor Complex Limited): SCL, based in Chandigarh, has been a pioneer in India’s semiconductor industry. It focuses on manufacturing specialized chips for strategic sectors, including space and defense. SCL is working on upgrading its facilities to enhance production capabilities and meet the growing demand for advanced semiconductors.

Opportunities

India’s semiconductor industry presents several compelling opportunities. Firstly, the domestic market is growing rapidly. With an expanding middle class and increasing digitization, the demand for electronic devices is surging, creating a robust market for semiconductors. This growth is driven by various sectors including automotive, consumer electronics, telecommunications, and IoT devices. Each of these sectors is seeing significant technological advancements, further fueling the demand for sophisticated semiconductor components.

India’s strategic geopolitical positioning also offers a unique opportunity. Amid global supply chain disruptions and geopolitical tensions, many countries are seeking to diversify their supply chains away from traditional hubs like China. India, with its stable political environment and strategic location, is well-positioned to become an alternative semiconductor manufacturing hub.

Another significant opportunity lies in India’s skilled workforce. The country has a vast pool of engineers and IT professionals, many of whom have experience in semiconductor design and software development. This talent pool can be leveraged to build a robust semiconductor manufacturing and design ecosystem.

Government support through various policy measures and incentives provides a conducive environment for the growth of the semiconductor industry. These initiatives aim to attract global investments, foster innovation, and enhance manufacturing capabilities, creating a favorable ecosystem for the semiconductor sector to thrive.

Challenges

Despite these opportunities, India’s semiconductor industry faces several challenges. One of the most significant is the high capital expenditure required to set up semiconductor manufacturing units. Establishing a semiconductor fab involves substantial investment, often running into billions of dollars. This high entry barrier can deter potential investors.

Supply chain issues also pose a significant challenge. India currently lacks a comprehensive supply chain for semiconductor manufacturing, including the availability of raw materials, specialized equipment, and ancillary services. Developing this supply chain is crucial to support domestic manufacturing.

The need for technological expertise is another critical challenge. While India has a strong IT sector, semiconductor manufacturing processes are highly specialized and complex. Building expertise in these processes will require significant investment in training and development.

Infrastructure is another area that needs attention. Robust infrastructure, including stable power supply, water availability, and advanced logistics, is essential for semiconductor manufacturing. Addressing these infrastructure gaps is crucial to support the growth of the semiconductor industry.

Outlook for 2024

The semiconductor industry in India is poised for significant growth in 2024, driven by several key factors including government initiatives, increasing demand for electronic devices, and advancements in technology. Here’s a detailed look at the outlook for this burgeoning sector:

Government Initiatives and Policies

The Indian government has been actively promoting the semiconductor sector through various initiatives and policy measures. The “Semicon India” program with an financial outlay of Rs 76,000 crore aims to make India a global hub for semiconductor design, manufacturing, and innovation. Substantial incentives, including production-linked incentives (PLI) and infrastructure support, are being provided to attract major global players and boost domestic capabilities.

Investments and Collaborations

2024 is expected to witness a surge in investments from both domestic and international companies. Collaborations with global tech giants are on the rise, bringing in advanced technologies and expertise. Companies like TSMC, Intel, and Samsung are exploring opportunities in India, signaling strong confidence in the country’s potential as a semiconductor hub.

Rising Demand for Semiconductors

The demand for semiconductors in India is rapidly increasing due to the proliferation of smartphones, IoT devices, automotive electronics, and consumer electronics. The rollout of 5G technology is further expected to drive demand for advanced semiconductor components. This surge in demand is likely to accelerate the growth of the semiconductor industry in 2024.

Development of Semiconductor Manufacturing Ecosystem

India is making significant strides in developing a robust semiconductor manufacturing ecosystem. New fabrication plants and semiconductor manufacturing units are being established with the support of the government and private sector investments. These developments are expected to enhance India’s manufacturing capabilities and reduce dependency on imports.

Focus on R&D and Innovation

Innovation and research and development (R&D) are key drivers for the semiconductor industry. India’s focus on establishing semiconductor R&D centers and fostering innovation through collaborations with academic institutions and research organizations is expected to yield cutting-edge technologies and products. This focus on R&D will be instrumental in positioning India as a leader in the global semiconductor market.

Talent Development and Skill Enhancement

The availability of skilled talent is crucial for the growth of the semiconductor industry. India is investing in educational programs and training initiatives to develop a highly skilled workforce. Partnerships with leading technology institutes and universities are aimed at equipping professionals with the necessary skills and knowledge to thrive in the semiconductor sector.

Legal Battle Over IT Act Intensifies Amid Musk’s India Plans

The outcome of the legal dispute between X Corp and the Indian government c...

Wipro inks 10-year deal with Phoenix Group's ReAssure UK worth

The agreement, executed through Wipro and its 100% subsidiary,...

Centre announces that DPDP Rules nearing Finalisation by April

The government seeks to refine the rules for robust data protection, ensuri...

Home Ministry cracks down on PoS agents in digital arrest scam

Digital arrest scams are a growing cybercrime where victims are coerced or ...

Icons Of India : Dilip Asbe

At present, Dilip Asbe is heading National Payments Corporation of Ind...

ICONS OF INDIA : SHAILENDER KUMAR

Shailender Kumar is senior vice president and regional managing direct...

Icons Of India : Bhavish Aggarwal

Indian entrepreneur Bhavish Aggarwal is the CEO of Ola, India’s larg...

ECIL - Electronics Corporation of India Limited

ECIL is distinguished by its diverse technological capabilities and it...

LIC - Life Insurance Corporation of India

LIC is the largest state-owned life insurance company in India...

CSC - Common Service Centres

CSC initiative in India is a strategic cornerstone of the Digital Indi...

Indian Tech Talent Excelling The Tech World - Aman Bhutani, CEO, GoDaddy

Aman Bhutani, the self-taught techie and CEO of GoDaddy, oversees a co...

Indian Tech Talent Excelling The Tech World - Sundar Pichai, CEO- Alphabet Inc.

Sundar Pichai, the CEO of Google and its parent company Alphabet Inc.,...

Indian Tech Talent Excelling The Tech World - Sanjay Mehrotra, CEO- Micron Technology

Sanjay Mehrotra, the President and CEO of Micron Technology, is at the...

of images belongs to the respective copyright holders

of images belongs to the respective copyright holders