Industrial IoT is driving the economic growth

By MYBRANDBOOK

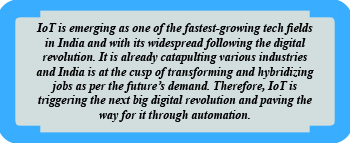

Indian IoT industry is paving way for the next big digital revolution

The digital revolution which will be powered by IoT creates a network of billions of people around the world through the internet. IoT, which stands for Internet of Things, is a network of physical objects which communicates and interacts with their internal states or external environment through embedded internet. This makes all the IoT devices around us easy to control and enable automation through the internet. A report states, 92% of industrial organizations will have adopted IoT technology and 77% believe it will transform manufacturing.

It is being supported by the Increasing Internet penetration along with the increasing intervention of the government to create a digitally developed country. IoT has been gaining popularity and it will trigger growth in job avenues, hybridize the traditional jobs, catapult industrial productivity and maybe even change the socio-economic fabric of India.

Integrating IoT-powered solutions will not only increase the production levels but will significantly boost the quality of production thereby impacting the revenue increase. The IoT technology helps monitor the machines in real-time and generates accurate reports for better decisions. According to Gartner, the worldwide IoT-connected devices are likely to increase to 43 billion by 2023. One of the primary reasons for this swift rise is the acceleration of digital transformation and the growth of 5G networks.

In IoT there are many security challenges that are less known by IT and by OT people. There are different technologies whereby security by design must take center stage in an integrated way. And even then, it’s not just a matter of applying some security frameworks but also about asking sound questions about IoT security on the short and long term, and about relying on vendors, partners and experts who follow what the ‘bad guys’ do closely as they are working in increasingly sophisticated ways.

Manufacturing businesses stand to make tremendous gains by adopting Industrial Internet of Things (IIoT) technologies. Ignoring the transformative opportunity risks competitive disadvantage, given that other companies in the same space will grab the opportunity to become more efficient and productive. According to a report by Accenture, the Gross Domestic Product of the U.S. could increase by more than $7 trillion by 2030 due to the efficiency and productivity gains on offer, while globally gains could go up by over $14 trillion.

Bringing key ingredients together is what really differentiates the IIoT from traditional ways of capturing and analyzing manufacturing data. The technologies include:

Smart, digital sensors that are affordable to deploy in the huge numbers needed to monitor almost any parameter in an industrial environment or process: motor speed, vibration, inspection data, etc.

Smart, digital sensors that are affordable to deploy in the huge numbers needed to monitor almost any parameter in an industrial environment or process: motor speed, vibration, inspection data, etc.

Wireless networking technologies include point-to-point and mesh networking that allows connecting large numbers of sensors with minimal additional cabled connections, which can be disruptive to install and potentially unreliable.

IIoT-friendly communication protocols such as Open Platform Communication Unified Architecture (OPC UA), which is platform-independent and leverages internet standards such as TCP/IP and HTTP(S) that promote seamless machine-to-machine communication.

Low-power IC technologies, as well as energy harvesting and storage, that enable deployment in almost any location.

The accessibility of high-performance computing, affordable even to small organizations on an “as-a-service” basis, in the cloud and moving toward the edge (including AI, which is well suited to pattern recognition tasks that are fundamental to analyzing sensor data).

Developments in data science, aided and abetted by the ongoing increases in computing performance to capture and crunch vast quantities of data (Big Data) from ubiquitous sensors. This can reveal otherwise undiscoverable insights into the numerous causes and effects that occur within every process happening inside the factory.

Leveraging IIoT technologies to create a smart factory offers tremendous opportunities. On the other hand, IIoT’s almost limitless scope and complex many-faceted nature can present barriers to taking that first step. There is the prospect of installing and onboarding thousands upon thousands of sensors, noting also that legacy equipment can present barriers to implementation. Then there is the challenge of managing the data produced. Each machine in a factory could generate as much as 5GB of data per week, amounting to about 5 petabytes (5 million GB) across all assets in a typical factory.

Starting small may help. Begin by collecting data from selected equipment or processes (perhaps the easiest to understand or those known to be under performing) and connect to cloud-based analytics services. Working with a partner that can offer various building blocks and services can demystify and shorten the learning curve. Avnet has a variety of proof-of-concept platforms with flexible connectivity options ready to start sending data to the cloud. Real-time analytics applications, REST APIs and SDKs are also provided for easy development, and lifecycle services are available to accelerate implementation and aid maintenance.

Moving forward, test programs can scale quickly by adding more sensors, monitoring additional equipment and processes, and performing more diverse analyses. Also, the value of the data can be assessed or filtered to capture events of interest. Basic data processing and filtering can be done at the edge of the network using edge controllers, smart gateways or aggregators. This can reduce network traffic, data storage and cloud workload, as well as enhance real-time performance.

In 2022, IoT will be firmly entrenched in people’s everyday lives. The number of devices connected to the IoT will triple by 2022, reaching 25 billion. Most cars and homes will be connected to the internet by 2022. Both individuals and companies will benefit from this connectivity.

IoT makes the autonomous collection of big data possible, which helps businesses get insights into customer behaviours and product performance. IoT also facilitates the continuous optimization and automation of business processes and even helps to improve employee engagement and performance.

There are six significant IoT security challenges:

• Weak password protection

• Lack of regular patches and updates and weak update mechanism

• Insecure interfaces

• Insufficient data protection

• Poor IoT device management

• The IoT skills gap

What has held back IoT adoption in India

• Lack of clarity on what to prioritize

• Lack of vision and short-term value realization

• Lack of right talent and skills for implementing and maintaining

IoT ecosystem

• Technical challenges of connectivity, compatibility,

interoperability, and cybersecurity

Key concerns

The biggest challenges related to IoT deployments are lack of strategy. Often, enterprises deploy IoT without having detailed planning around its implementation need and future-focused vision. Concerns related to data ownership, privacy, compliance, and algorithm bias can put CIOs in a difficult position.

Regarding IoT deployment concerns, the most significant ones are security, especially when it comes to multi-site operations. Connected devices can be controlled by hackers for their nefarious means. Imagine, someone taking control of the different devices being operated in factories, houses, enterprises.

According to a HP study, 70 percent of the most commonly used Internet of Things (IoT) devices contain vulnerabilities, including password security, encryption and general lack of granular user access permissions.

“This spike in demand (for IoT) is pushing manufacturers to quickly bring to market connected devices, cloud access capabilities and mobile applications in order to gain share. While this increase in IoT devices promises benefits to consumers, it also opens the doors for security threats ranging from software vulnerabilities to denial-of-service (DOS) attacks to weak passwords and cross-site scripting vulnerabilities,” HP notes.

Various vulnerabilities and threats which have emerged with the rise of IoT needs to be tackled by enterprises by implementing end-to-end security approach to scan and identify the network security flaws before they become serious issues.

Enterprises will be required to explore technologies such as SD-WAN to resolve the issues related to IoT security. With IoT, the role of network administrators will become more complex as they will need to keep a consistent check through remote management. Robust authentication policies will be required to prevent attacks from IoT devices to other network sites.

A recent Technology Industry Innovation study by KPMG states that IoT is ranked as the top technology to have the tremendous potential to drive future business transformation and long-term value, especially around improved business efficiencies, increased profitability, and cost reduction. However, according to the study, the biggest challenge in fully embracing the IoT by enterprises is to shape a new relationship between organizations, customers, and others operating in their supply chain.

One of the ways to develop the relationship is to analyze data from a connected ecosystem, the KPMG report states. “Thus, building trust with customers and suppliers who want to know their data is secure, and for organizations to make informed business decisions, knowing they can trust the data collected,” it says.

Another challenge that creates a hindrance in the mass-level adoption of IoT among enterprises is the lack of robust mobile broadband connectivity. Large-scale transformations cannot be achieved consistently based on 2G/3G/4G or even in wired infrastructure. Because these technologies are either slow or have latency issues, or they may use an exorbitant amount of energy to support IIoT. The fifth generation of technology can become really useful in this case. When powered with 5G speed and AI-based analytics, manufacturers can forecast problems, analyze them in real-time, and curtail production downtime.

One of India’s leading IT services firms, Wipro, in a report, states that because of the high capacity, wireless flexibility, and low-latency performance of 5G, IIoT deployments in the manufacturing segment will see strong demand. In such a scenario, 5G has the potential to enable high-speed connectivity without the cost and complexity of fiber optic cables. And this makes 5G a natural choice for high precision manufacturing environments.

In addition, the sensors market will likely evolve considerably during the next three to four years. In the post COVID world, where businesses are going hybrid ways of working, sensor monitoring solutions will play a pivotal role in IoT-related projects.

Google promotes Sanjay Gupta as APAC President

Sanjay Gupta, who is the present Country Manager - India for Google has be...

Supreme Court verdicts against NEET Re-Examination

The Supreme Court declared that there will be no retest for the NEET-UG e...

Government brings in three employment-linked incentive program

The Finance Minister unveiled three new incentive programs in the Union ...

Amazon may soon launch new AI-powered Alexa

Amazon has been previewing an all-new Alexa which will be based on a new l...

ICONS OF INDIA : SANJAY NAYAR

Sanjay Nayar is a senior finance professional in the Indian private in...

Icons Of India : GAUTAM ADANI CHAIRMAN ADANI GROUP

Gautam Adani is the Founder and Chairman of the Adani Group, which ran...

Icons Of India : NEERAJ MITTAL

He started his career as an IAS Officer in 1992. He has held various a...

C-DAC - Centre for Development of Advanced Computing

C-DAC is uniquely positioned in the field of advanced computing...

CSC - Common Service Centres

CSC initiative in India is a strategic cornerstone of the Digital Indi...

IREDA - Indian Renewable Energy Development Agency Limited

IREDA is a specialized financial institution in India that facilitates...

Indian Tech Talent Excelling The Tech World - Shantanu Narayen, CEO- Adobe Systems Incorporated

Shantanu Narayen, CEO of Adobe Systems Incorporated, is renowned for h...

Indian Tech Talent Excelling The Tech World - Steve Sanghi, Executive Chair, Microchip

Steve Sanghi, the Executive Chair of Microchip Technology, has been a ...

Indian Tech Talent Excelling The Tech World - Thomas Kurian, CEO- Google Cloud

Thomas Kurian, the CEO of Google Cloud, has been instrumental in expan...